2013-2016 Ram Trucks 6.7L Diesel Engine Bench

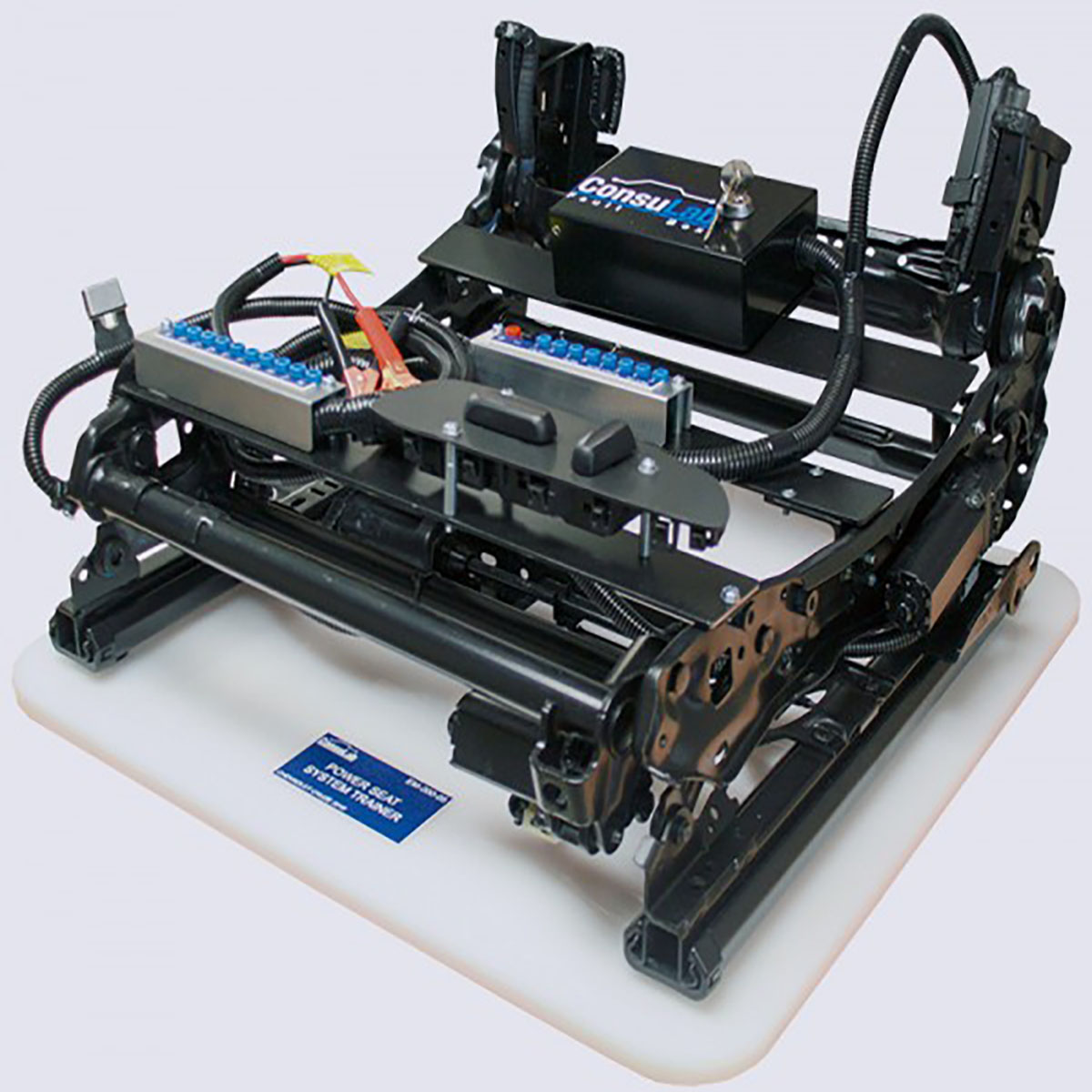

The diesel engine trainer is a fully operational engine mounted on a mobile stand. Trainer is based on 2016-2013 Ram Trucks w/Cummins 6.7L global engine platform. The trainer is easy to work on and all major components, wiring and connectors match OEM configuration. The trainer is mounted on a mobile stand constructed of 2” (5 cm) tubular steel equipped with four 5” (12.5 cm) phenol casters (2-fixed and 2-swivel w/locks). Students can perform many NATEF related Engine Performance and Electrical/Electronic tasks using this trainer. Trainer is equipped with safety guards covering all rotating components.

Educational Advantages

- Demonstration of systems to groups of students without the access limitations of a complete vehicle

- Engine system responds to inserted faults with real world symptoms, OEM DTC’s and check engine light operation

- Equipped with all OEM equipment related to EPA 2010 Emission Standards (with SCR)

Features

- High pressure common rail fuel system (Bosch)

- Automatic transmission

- OBDII data link connecter for scan tool hookup

- Integrated ECM breakout box with test points for oscilloscope and DMM hookup

- Breakout box terminals identified with OEM terminology and numbers

- Diesel Particulate Filter (DPF)

- Exhaust Gas Recirculation (EGR)

- Diesel Oxidation Catalyist (DOC)

- Selective Catalytic Reduction (SCR) w/ DEF injection

- Closed Crankcase Ventilation System

Specifications

The trainer is easy to work on and all major components, wiring and connectors match OEM configuration. The trainer is mounted on a mobile stand constructed of 2” (5 cm) tubular steel equipped with four 5” (12.5 cm) phenol casters (2-fixed and 2-swivel w/locks). Trainer is equipped with safety guards covering all rotating components.

2016-2013 Model Years

Standard Equipment

Optional Equipment