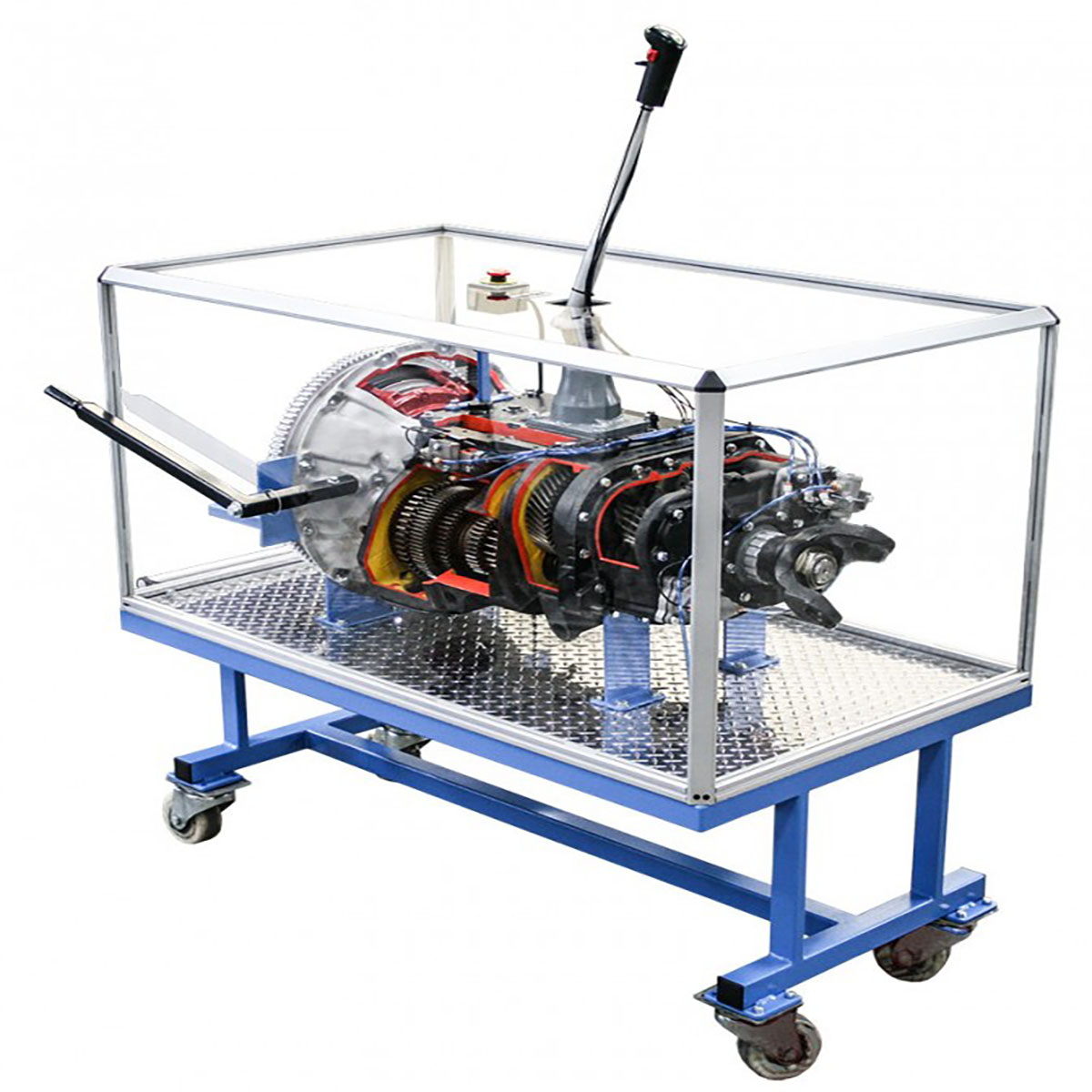

Hydrostatic Transmission – Implement And Steering

The FP-MF500-IS-TSE Hydrostatic Transmission Trainer features the exact transmission found in the vast majority of skid-steer loaders, mini-backhoes, and numerous other mobile and industrial machines. This trainer is provided with hydraulic steering and implement, and is available as a diesel engine-driven simulator or an electric motor-driven simulator. The trainer is equipped with a state-of-the-art, dual-drive, hydrostatic transmission system. The dual-pumps are electronically controlled with independent joysticks – just like the actual vehicle. The state-of the-art, electronically-controlled, wheel load system is designed to simulate any driving conditions, regardless of severity, that a typical hydrostatic drive might experience.

The trainer is equipped with a state-of-the-art, dual-drive, hydrostatic transmission system. The dual-pumps are electronically controlled with independent joysticks – just like the actual vehicle. The state-of the-art, electronically-controlled, wheel load system is designed to simulate any driving conditions, regardless of severity, that a typical hydrostatic drive might experience.

Features and benefits

- No wheels on the ground equals no unforeseen safety hazards

- No hazardous rotating wheels or moving tracks

- No fatigue – all components mounted waist high

- No slip hazards or environmental problems

- No confined spaces

- Five emergency stops

- Safe-T-Bleed®

- Industry standard lockout devices

- Real-time operation – drives as if it were on a construction site

- Built-in faults – unparalleled diagnostics teaching and learning capability

- Prepares students for the real world – teaches students “need to know” information

- Hydraulic implement and articulated steering module

- As an added convenience the load mechanism is equipped with an integral cylinder rebuild station, which is designed to permit two groups of students to disassemble/assemble cylinders at the same time

Prime Mover: Electric motor; 20HP (15 kw); TEFC; C-face; 1800 RPM; 3-phase – 460V

(optional 3-phase – 230V available)

Pumps: Dual, tandem-mount, axial piston type pumps; 138 bar (2000 PSI); 38 Lpm (10 GPM); electronic displacement control

Motors: Dual, high torque/low speed motors;

fixed displacement 82 cm3/rev. (5.0 in3/rev.)

Reservoir Capacity: 643 liters (170 gallons)

Dynamic Wheel Load: Independent left-hand and right-hand wheel drive with infinitely variable electronic load control in forward and reverse

Panel PC: Panel PC, Microsoft® WindowsTM software; 48 cm (19”) full-color touch-screen with pre- loaded learning software and diagnostic activities

Diagnostics: Pre-programmed activities covering every fault published in a typical hydrostatic transmission manufacturer’s troubleshooting flow charts

Safety Features:

Options

Prime Mover: Diesel drive

Pumps: Any make or type currently available,

e.g., Sauer Danfoss®, Rexroth®, Eaton®, Linde®, etc.

Pump Controls: Mechanical, hydraulic pilot

Motors: High-speed/Low torque, fixed or variable displacement motors

188cm (74.0”) tall x 163cm (64.0”) wide x 193cm (76.0”) long