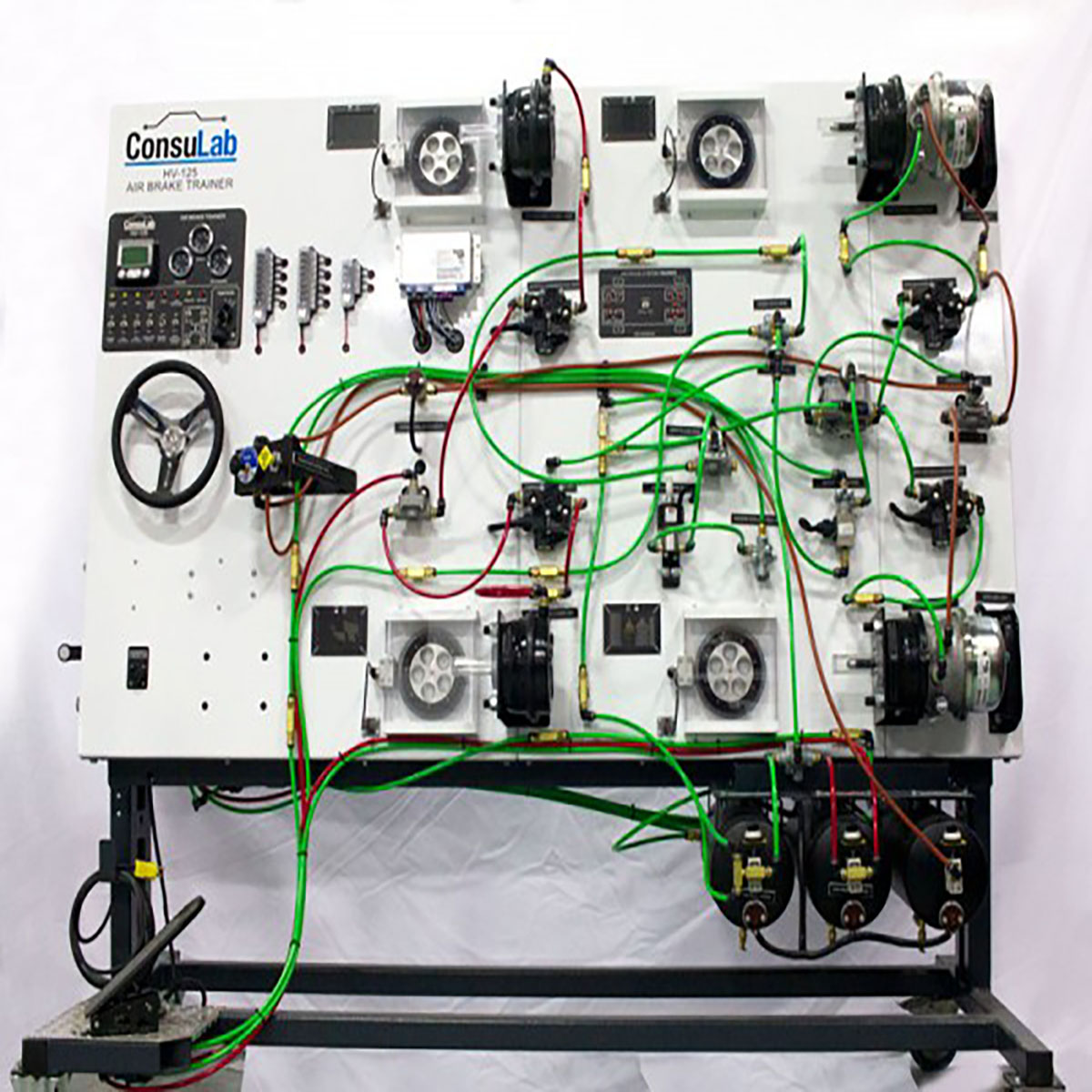

Diesel Engine Bench Detroit Diesel GHG17 Recycled

Specially built to meet all diesel engine performance and repair tasks. The recycled EPA 2013 Detroit Diesel DD15/DD16 diesel engine bench w/EGR, DPF, SCR, is mounted on a tubing steel stand. Completely operational and safe, this standard trainer is easy to work on and complies with manufacturer rules and specifications related to all OEM codes, colors and electronics.

Educational Advantages:

- Includes Student activities:

- Demonstration of major engine systems to groups of students without the access limitations of a complete vehicle.

- Engine systems respond to inserted faults with real world symptoms, OEM DTCs and MIL operation.

- Functional DLC using SAE J1939 communication protocol.

- Provides a platform to perform the following:

––Diagnose and troubleshoot fuel system;

––Diagnose and troubleshoot engine management system;

––Diagnose and troubleshoot electrical/electronic system;

––Obtain electronic parameters using diagnostic equipment;

––Obtain technical data and information from the trainers through an electronic service tool connection;

––Perform testing procedures of all electrical and mechanical systems;

––Allow user to exercise test procedures as outlined in OEM service manuals.

Application

- Detroit Diesel’s EPA13 equipped with recycled DD15 diesel engine and post-treatment system

Standard Equipment and Features:

Functional Post-treatment Systems :

Physical Specifications:

Remote Control Software

Educational Advantages:

Features:

Example Faults

Austin

Contact Us

Leading The Future of Teaching Tech™

GET IN TOUCH

Connect with Us

Let us partner with you to build premier automotive, diesel, and fluid power programs.