Suspension And Steering Trainer

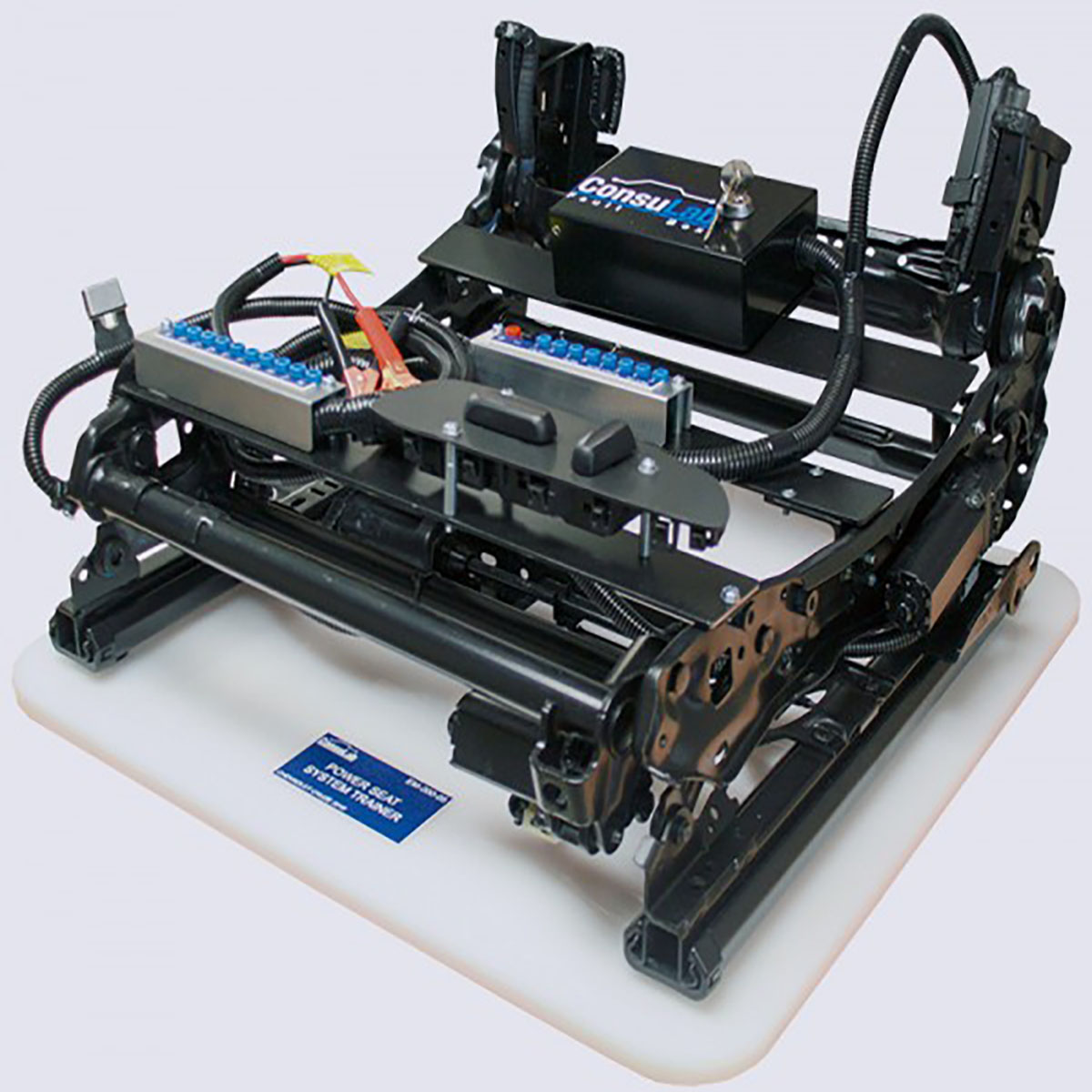

The EM-130 Suspension and Steering trainer is designed to assist instructors in teaching basic alignment geometry and the function of a MacPherson strut suspension system with rack & pinion steering. The trainer is extremely versatile in that students can easily visualize all component operation as well as practice adjusting the various alignment angles.

Educational Advantages:

The EM-130 trainer can be used to provide students with the following educational outcomes:

- Provides full accessibility of vehicle components without access limitations of a real vehicle

- Alignment demonstrations, measurement and adjustments can be accomplished with clear viewing by students

- Component identification of a typical MacPherson strut suspension system

- Component identification of a typical rack & pinion steering system

- Component identification of a typical sway & stabilizer bar

- Front bearing hub and wheel bearing service

- Make, measure and observe changes of Caster, Camber and Toe

The EM-130 trainer can be used for student identification of a typical disc brake system. Students can practice the following brake tasks:

- Wheel & tire service

- Brake caliper and rotor service

- Rotor (T.I.R.) runout and thickness measurements

- Brake condition inspection

The EM-130 trainer can be used for the instruction and practice of common MacPherson strut and rack & pinion steering service procedures including:

- Rack removal and reinstallation

- Inner & outer tie rod service

- Strut and ball joint service

The trainer allows superior component visualization and allows actual measurement of camber, caster and SAI using the included magnetic gauge. Students can easily make adjustments and view the results of the changes.

Students can also view the following alignment concepts on the trainer:

- SAI (STEERING AXIS INCLINATION)

- TOTAL INCLUDED ANGLE

- SIDE-TO-SIDE DIFFERENCES IN CASTER, CAMBER AND TOE.

The ConsuLab EM-130 Suspension and Steering trainer is designed to assist instructors in teaching basic alignment geometry and the func- tion of a MacPherson strut suspension system with rack & pinion steering. The trainer is extremely versatile in that students can easily visual- ize all component operation as well as practice adjusting the various alignment angles. The trainer is equipped with two movable turntables and a magnetic alignment measuring gauge to assist students in observing actual measurement and changes in alignment angles. Students can also visualize and learn common braking system components. The EM-130 trainer consists of a typical front wheel drive vehicle having MacPherson strut suspension, rack & pinion steering and front disc brakes. The components necessary for correct operation and service of alignment angle adjustments and component identification are included. The potential danger of the MacPherson spring pressures have been eliminated by replacing the stock coil spring with a custom plastic coil spring that does not support any of the weight of the suspension system. The lower control arm and support bushings are OEM.

The sway bar has been designed with a quick disconnect feature that allows students to disconnect it for easy and precise alignment adjust- ment procedures. The rack and pinion steering linkage is connected to a steering wheel identical to actual vehicle configuration. The tie-rod ends are equipped with typical adjustment methods for the adjustment of toe specifications. The trainers frame has three manual adjustment features that allow students to create abnormal vehicle conditions such as uneven front or rear loading, worn springs, etc. The trainer also features adjustment plates at the top of both MacPherson strut assemblies which allow easy adjustment of caster and camber. The tires sit on movable plates for ease of movement during adjustments. The trainer can also be used for student learning of front wheel bearing and hub construction as well as the disc brake system based on a 2012-2018 Hyundai Accent.

Specification:

MLR – MAINTENANCE & LIGHT REPAIR

Manual Drive Train & Axles

Steering & Suspension

Brakes

AST – AUTOMOTIVE SERVICE TECHNICIAN

ALL OF THE TASKS ABOVE FROM MLR PLUS THE FOLLOWING:

Steering & Suspension

MAST – MASTER AUTOMOTIVE SERVICE TECHNICIAN

Steering & Suspension